Marine Travelift Parts

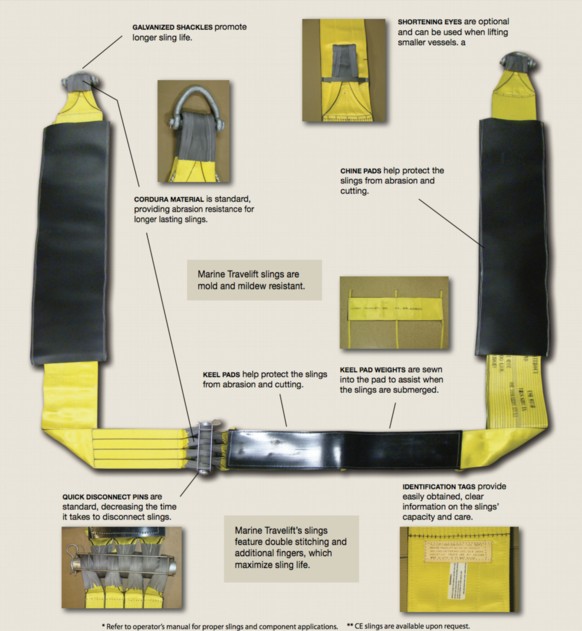

Slings

Slings are one of the most vital parts of any Marine Travelift. Inspecting and replacing the slings is imperative to securing the safety and productivity of your lift. If you or one of your crew sees any of the following indicated on your slings, please contact us immediately.

Slings must be removed from service if any of the following damage exists:

New Sling Features

Wire Rope

We are all looking for money saving ideas when it comes to running our businesses. From a service standpoint, wire rope maintenance is one way that every marina or boatyard can find long-term maintenance savings. The wire ropes on your mobile boat hoist make up a critical and expensive component of the overall safety and performance of your lift. Replacement of wire ropes is inevitable on any piece of equipment, but the frequency of such a service is completely in your control. To help explain how to extend the life of these important items, it is first important to know their basics.

The wire ropes on your machine have three basic components:

The core is a smaller rope, which is similar in looks to the outer strands. Each wire rope is made this way to provide maximum lifting strength and to help prevent crushing damage to the outer strands.

Do any of the following conditions exist on your Wire Rope?

If the answer is yes to any of these questions, it’s time to purchase a new wire rope for your Marine Travelift Boat Hoist.

Wire Rope Lubricant

Martin Walter Company's wire rope lubricant is designed primarily for hoist ropes and working ropes in the marine environment. It provides excellent lubricity and corrosion protection while minimizing sling-off. It has a tackifier to assure adhesion to the wire rope, even in wet and high-speed operations. It is made with extreme pressure and anti-wear additives for heavy-duty work and contains no solvents and will not dry, harden or evaporate. It protects against corrosion and resists water washout, acids, dirt, salt, steam, chlorine, H2S, and CO2. It is manufactured to work in temperatures from -60F to 380◦F and is essentially non-conductive, non-flammable, non-toxic, and biodegradable.

Sold in 5-gallon containers. Contact Martin Walter today for pricing. Protect your wire rope investment. Marine Travelift recommends lubricating your wire rope monthly to lubricate and prevent corrosion.

Physical Properties

Appearance

Amber

Flash Point

390°F

Auto Ignition

555°F

Pour Point

- 60°F

Freezing Point

-110°F

API Gravity

24.8

Kinematic Viscosity at 40° C

20.04

Coefficient of Friction Mu Value

.23/.25

Four-Ball Wear Test

4mm+.02

Four-Ball Weld

220 Kg

Weld Point (ASTM266)

315 Kg

Rust Resistance (ASTM D-665)

Pass

Hydrochloric Acid Fumes (7 Day Exp)

No Metal Loss

Environmental Impact

Biodegradable

Precipitation

Trace

Toxicity

Non-Toxic

Copper Corrosion Test

1a

Dielectric Strength

27 Kv

Load Wear Index

32.93

Application: Easily applied by spraying, brushing, dripping, or pressure applicator.

Safety & Disposal: Wire Rope Lubricant is essentially non-flammable and is classified as a non-hazardous material. Use chemical resistant gloves and protective eyewear when applying. Refer to local, state, and federal regulations for proper disposal.

Parts Request

Insert your information below & someone from our office will be in contact to confirm your order and collect payment information.